Introduction: Rotary Kiln is also referred to cement rotary kiln, limestone rotary kiln and clinker rotary kiln, which is usually used to calcine cement clinker. It is also core equipment of new type of dry process cement production line.

Rotary Kiln is also referred to cement rotary kiln, limestone rotary kiln and clinker rotary kiln, which is usually used to calcine cement clinker. It is also core equipment of new type of dry process cement production line. In addition, limestone rotary kiln can also be used as calcining equipment of limestone. In limestone production line, rotary kiln is usually used to calcine limestone, thus making limestone decomposed.

Henan Ling Heng Machinery can produce rotary kiln with diameter Ø1-Ø5m, which is widely used in metallurgy, steel, chemical, refractory, ceramsite, papermaking industries. The magnetization roasting of lean iron ore of steelworks can also use rotary kiln. The lean iron ore after roasting has magnetic, which can be used for magnetic separation work. The rotary kiln has such advantages as reliable performance, high yield and low energy consumption.

The Classification of Rotary Kiln

1. According to the usage: it can be divided into magnesium metal rotary kiln, ceramsite sand rotary kiln, lime rotary kiln, etc.

2. According to the processing materials: it can be divided into cement kiln, metallurgy chemical kiln and lime kiln.

Rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. Raw materials after grinding will be burned into clinker under the action of high temperature of cement rotary kiln. Hence, cement rotary kiln also is commonly known as the heart of cement plant.

Structure of Rotary Kiln

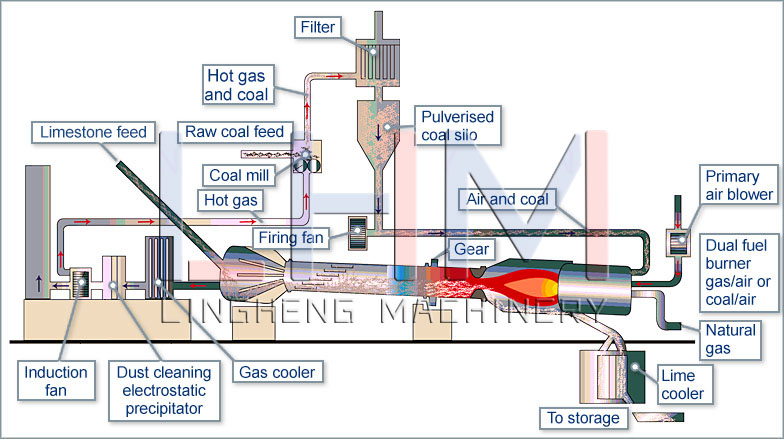

Rotary kiln is composed of the shell, the supporting device, the supporting device with thrust roller, the driving device, the movable kiln head, the sealing device at kiln tail, the combustion device, etc.

It has the simple structure and reliable operation, at the same the production process of the rotary kiln can be controlled easily.

Materials produced using rotary kilns include: Cement; Lime; Refractories; Metakaolin; Titanium dioxide; Alumina; Vermiculite; Iron ore pellets. They are also used for roasting a wide variety of sulfide ores prior to metal extraction.

Features of Rotary Kiln

1. Reliable operation; 2. High quality production material; 3. High strength and optimum performance; 4. Reasonable design and economic operation cost; 5. Low power consumption; 6. Environment friendly; 7. Double benefits from recycling.

Working Principle of Rotary Kiln

The kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis.

The material to be processed is fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down towards the lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln, sometimes in the same direction as the process material (co-current), but usually in the opposite direction (counter-current).

The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burner-pipe (or "firing pipe") which acts like a large bunsen burner. The fuel for this may be gas, oil, pulverized petroleum coke or pulverized coal.

Technology Data of Rotary Kiln

| Type | Technical parameters | Reduction drive | Main motor | Support quantity | Weight (T) | |||||

| Rotation speed (r/min) | Obliquity (%) | Output (t/h) | Type | Ratio | Type | Power (KW) | Rotation speed (r/min) | |||

| Ø1.6*32 | 0.158-0.258 | 3 | 0.6-2 | PM750 | 48.57 | JZJY61-4 | 15 | 1200/120 | 3 | 46.82 |

| Ø1.8*45 | 0.66-1.98 | 4 | 1-4.5 | UT2-110 | 163.36 | JZS-81 | 30/10 | 1410/470 | 3 | 68 |

| Ø1.9/Ø1.6*36 | 0.53-1.59 | 4 | 2.5-3 | JZQ750-I | 48.85 | JZT-72-4 | 30 | 1200/400 | 3 | 53 |

| Ø2.1/Ø1.8*36 | 0.5-1.51 | 4 | 4 | UT2-110 | 163.36 | JZS-81 | 30/10 | 1410/470 | 3 | 75 |

| Ø2.2*50 | 0.125-1.25 | 3.5 | 5 | ZS145-11 | 157 | YCT280-4A | 30 | 1320/132 | 3 | 130.71 |

| Ø2.5*50 | 0.516-1.549 | 3.5 | 8 | ZS165-7 | 99.96 | YCT355-4A | 55 | 1320/140 | 3 | 167.5 |

| Ø3*48 | 0.3309-3.309 | 3.5 | 28 | ZI130-14 | 32.11 | ZSN4-250-21B | 90 | 1000/100 | 3 | 237 |

| Ø3.2*50 | 0.398-3.975 | 3.5 | 42 | ZI130-16 | 40.85 | ZSN4-280-11B | 190 | 1500/150 | 3 | 263 |

| Ø3.3*52 | 0.91-3.91 | 3.5 | 50 | ZSY500-28 | 27.707 | ZSN4-315-082 | 190 | 1000/100 | 3 | 280.8 |

| Ø3.6*55 | 3.5 | 3.5 | 76 | ZS117-5-II | 79.2 | ZSN-280-11B | 125 | 1000/200 | 4 | 368.7 |

| Ø4*60 | 0.396-3.96 | 3.5 | 105 | ZSY630-35.5 | 34.601 | ZSN4-355-092 | 315 | 1000/100 | 4 | 487.5 |

| Ø4.2*60 | 0.4165-4.165 | 3.5 | 143 | ZSY710-35.5 | 35.526 | ZSN4-355-12 | 420 | 1000/100 | 4 | 556.1 |

| Ø4.5*65 | 0.46-1.45 | 4 | 168 | JH800C-SW306 | 35.5 | ZSN4-400-22 | 560 | 1000/100 | 4 | 710 |

| Ø4.8*74 | 0.35-4 | 4 | 208 | JH710C-SW305-40 | 42.226 | ZSN4-400-092 | 630 | 1500/130 | 4 | 841 |

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!