Introduction: The round vibrating screen or the circular vibrating screen is a high efficient vibrating screen with many layers. Circular vibrating screen adopts the cylinder eccentric shaft exciter and the amplitude adjustment device. Its material screening line is quite long and there are many types of screening specifications.

The round vibrating screen or the circular vibrating screen is a high efficient vibrating screen with many layers. Circular vibrating screen adopts the cylinder eccentric shaft exciter and the amplitude adjustment device. Its material screening line is quite long and there are many types of screening specifications. We often use the vibrating screens to separate sand and stones. The circular vibrating screen can also be applied in the industries of coal dressing, ore beneficiation, construction material, electric power and chemical engineering.

Vibrating Screen is a kind of screening equipment which relies on different amplitudes to screen out materials with different granularities and then move to the next working procedure. The difference between circular vibrating screen and linear vibrating screen is that circular vibrating screen is doing circular motion, which is a new type of multi layers and efficient screening equipment.

Vibrating Screen is the essential screening equipment in all kinds of sand production lines, which is mainly used for the screening of dry materials in metallurgy, coal, ore and other materials. It is widely used for products classification in mining, building materials, transportation, energy, chemical industry and other industries. Vibration screen also has other names, such as vibratory screen and vibrating screen machine.

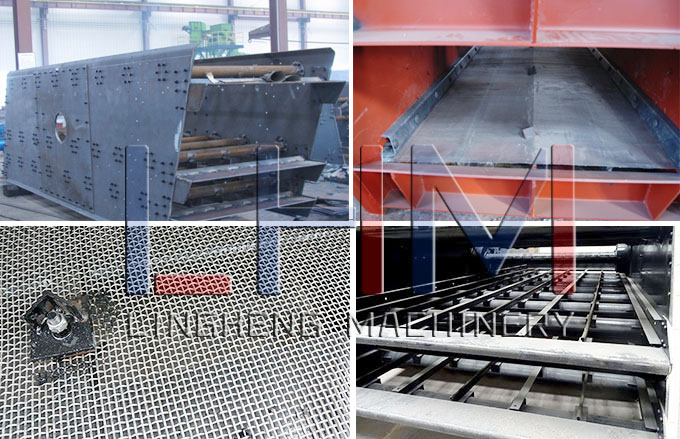

Vibrating Screen is mainly composed of the screen box, vibration exciter, suspension (or supporting) devices, electric motors, etc. Motor drives the spindle to rotate through the belt. Due to the unbalanced centrifugal inertia force of heavy objects in the vibration exciter, the vibrating screen box will get vibration force. Changing the exciter eccentric weight can get different amplitude.

Vibrating Screen adopts eccentric block structure, which has simple structure; it can be equipped with the feeding box, which can not only increase the effective screening area of the vibration screen, but also prolong the service life of the screen feeding end; the transmission part increases the intermediate bearing seat to protect the motor, and prolongs the duration of motor. The adjustment of screen angle can be realized by changing the height of spring frame position.

Working Principle of Vibrating Screen

Circular vibrating screen is single-axis circular-movement inertial vibrating screen, whose working depends on inertial motor and inertial strength produced by eccentric plate. Because of the vibration of screen box, the materials are thrown out, so that materials of certain size go through the screen mesh, and the screening aim is realized. Since the magnetic exciter is installed on the gravity center of screen box, the two long elliptical axis form a shape like a Chinese character, and the upper of long elliptical axis at inlet end is in the same direction with the outlet, which favors the spread of materials which are at the screen box. However, the upper of long elliptical axis at outlet end is opposite to the direction of the outlet, which can reduce the movement speed of materials, and help the difficult-screened materials go through the screen mesh. What's more, the effective area of screen is increased because of the elliptical screen surface; as a result, the processing capacity is promoted.

Details about Screening Process

The screening process can be divided into three stages, the first screening of the crude ores, the second screening before the burning, the fine screening with the strong magnetic and weak magnetic beneficiation and the residue removing screening in the process of the strong magnet beneficiation.

The detailed screening process is that the crude ores are screened for the first time and two kinds of products can be got: powder ore and lump ore. The lump ore will be screened for the second time and then goes into the shaft furnace for roasting, and the powder ore will directly go into the strong magnet beneficiation process for screening. Hydro cyclone equipment and spiral grading machine belong to gravity grading equipment which means that these machines grade materials with the sedimentation theory and the grading efficiency is very low. Generally speaking, it is 30% to 40%.

Technical Data of Vibrating Screen

| Model |

Sieve layer |

Sieve area (m2) |

Mesh size (mm) |

Max. feeding size (mm) |

Processing capacity (m³/h) |

Vibrating Frequency (r/min) |

Double amplitude (mm) |

Motor power (kw) |

Sieve obliquity (o) |

Sieve specification (mm) |

Total weight (kg) |

Dimensions (L*W*H) (mm) |

| 2YK1225 | 2 | 6 | 4-50 | 400 | 8-60 | 800-970 | 8 | 5.5 | 20 | 1200*2500 | 3500 | 2930*1860*870 |

| 3YK1225 | 3 | 9 | 4-50 | 400 | 10-70 | 800-970 | 8 | 5.5 | 20 | 1200*2500 | 3850 | 3070*1860*1210 |

| 2YK1230 | 2 | 7.2 | 4-50 | 400 | 12-78 | 800-970 | 8 | 7.5 | 20 | 1200*3000 | 4200 | 3430*1860*870 |

| 3YK1230 | 3 | 10.8 | 4-50 | 400 | 13-80 | 800-970 | 8 | 7.5 | 20 | 1200*3700 | 4600 | 3570*1860*1210 |

| 2YK1237 | 2 | 8.88 | 4-50 | 400 | 15-86 | 800-970 | 8 | 7.5 | 20 | 1200*3700 | 4600 | 4050*1860*870 |

| 3YK1237 | 3 | 13.32 | 4-50 | 400 | 16-90 | 800-970 | 8 | 7.5 | 20 | 1500*3500 | 5200 | 4270*1860*1210 |

| 2YK1535 | 2 | 10.5 | 5-50 | 400 | 20-125 | 800-970 | 8 | 11 | 20 | 1500*3500 | 5890 | 4120*2210*1230 |

| 3YK1535 | 3 | 15.75 | 5-50 | 400 | 21-125 | 800-970 | 8 | 11 | 20 | 1500*3500 | 6700 | 4360*2210*1610 |

| 2YK1545 | 2 | 13.5 | 5-50 | 400 | 22-150 | 800-970 | 8 | 15 | 20 | 1500*4500 | 6330 | 5120*2210*1230 |

| 3YK1545 | 3 | 20.25 | 5-50 | 400 | 22-150 | 800-970 | 8 | 15 | 20 | 1500*4500 | 6800 | 5360*2210*1610 |

| 4YK1545 | 4 | 27 | 5-50 | 400 | 22-155 | 800-970 | 8 | 18.5 | 20 | 1500*4500 | 7800 | 5930*2210*2060 |

| 2YK1548 | 2 | 14.4 | 5-50 | 400 | 22.5-162 | 800-970 | 8 | 15 | 20 | 1500*4800 | 6980 | 5420*2210*1230 |

| 3YK1548 | 3 | 21.6 | 5-50 | 400 | 22.5-162 | 800-970 | 11 | 15 | 20 | 1500*4800 | 7700 | 5660*2210*1610 |

| 4YK1548 | 4 | 28.8 | 5-50 | 400 | 22.5-162 | 800-970 | 8 | 18.5 | 20 | 1500*4800 | 8700 | 6230*2210*2060 |

| 2YK1848 | 2 | 17.28 | 5-80 | 400 | 25-206 | 750 | 8 | 15 | 20 | 1800*4800 | 9080 | 5420*2550*1420 |

| 3YK1848 | 3 | 25.92 | 5-80 | 400 | 32-276 | 750 | 8 | 18.5 | 20 | 1800*4800 | 9600 | 5660*2550*1780 |

| 4YK1848 | 4 | 34.56 | 5-80 | 400 | 32-285 | 750 | 8 | 22 | 20 | 1800*4800 | 11100 | 6290*2550*2160 |

| 2YK1854 | 2 | 19.44 | 5-80 | 400 | 32-312 | 800-970 | 8 | 18.5 | 20 | 1800*5400 | 10150 | 5960*2550*1420 |

| 3YK1854 | 3 | 29.16 | 5-80 | 400 | 32-312 | 800-970 | 8 | 22 | 20 | 1800*5400 | 10840 | 6260*2550*1780 |

| 4YK1854 | 4 | 38.88 | 5-80 | 400 | 32-336 | 800-970 | 8 | 30 | 20 | 1800*5400 | 12840 | 6830*2550*2160 |

| 2YK2160 | 2 | 25.2 | 5-100 | 400 | 50-475 | 970 | 8 | 30 | 20 | 2100*2600 | 11780 | 6720*2840*1530 |

| 3YK2160 | 3 | 37.8 | 5-100 | 400 | 50-475 | 970 | 8 | 30 | 20 | 2100*2600 | 12800 | 7030*2840*1910 |

| 4YK2160 | 4 | 50.4 | 5-100 | 400 | 50-497 | 970 | 8 | 37 | 20 | 2100*2600 | 14800 | 7300*2840*2380 |

| 2YK2460 | 2 | 28.8 | 5-100 | 400 | 65-550 | 970 | 8 | 37 | 20 | 2400*6000 | 15600 | 7020*3140*1530 |

| 3YK2460 | 3 | 43.2 | 5-100 | 400 | 70-620 | 970 | 8 | 37 | 20 | 2400*6000 | 17600 | 7300*3140*1910 |

| 4YK2460 | 4 | 57.6 | 5-100 | 400 | 80-680 | 970 | 8 | 45 | 20 | 2400*6000 | 19600 | 7600*3140*2380 |

| 2YK2870 | 2 | 39.2 | 5-100 | 400 | 120-680 | 750 | 8 | 22*2 | 20 | 2800*7000 | 21200 | 7600*4320*1620 |

| 3YK2870 | 3 | 58.8 | 5-100 | 400 | 180-720 | 750 | 8 | 22*2 | 20 | 2800*7000 | 22400 | 7800*4320*2120 |

| 2YK3072 | 2 | 43.2 | 5-100 | 400 | 200-700 | 750 | 8 | 22*2 | 20 | 3000*7200 | 23600 | 7800*4520*1750 |

| 3YK3072 | 3 | 64.8 | 5-100 | 400 | 230-800 | 750 | 8 | 22*2 | 20 | 3000*7200 | 25500 | 8000*4520*2300 |

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!