Introduction: The Wet Pan Mill is also called wet grinding mill or gold grinding machine. It is praised by users becauseof it has the features of low investment,high production capacity,low consumption,good efficiency,easy installation and maintenance.It is the excellent equipment which can instead f ball mill.

The Wet Pan Mill is also called wet grinding mill or gold grinding machine. It is praised by users becauseof it has the features of low investment,high production capacity,low consumption,good efficiency,easy installation and maintenance.It is the excellent equipment which can instead f ball mill. It is perfect equipment for medium sized and small enterprieses. The wet grinding mill is mainly used for separating gold,sliver,lead,zinc,iron,molybdenum,copper,antinomy and so on.

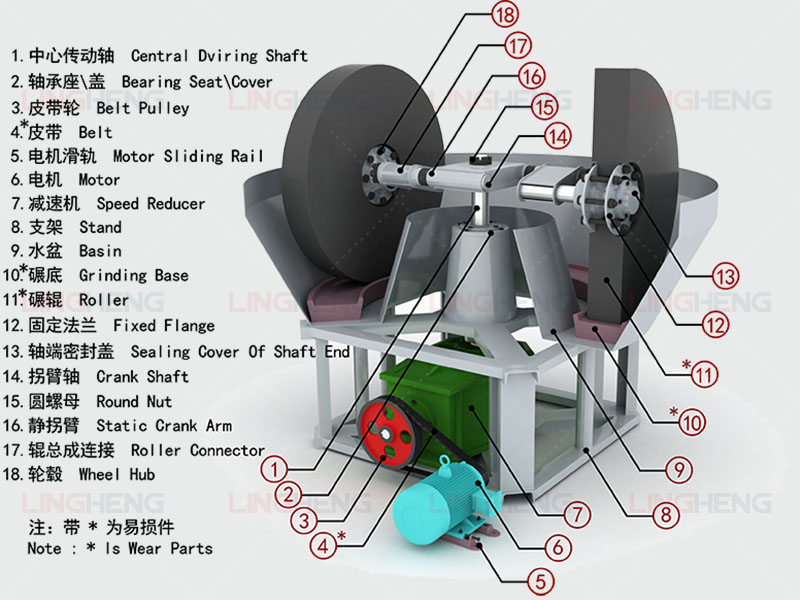

Wet Pan Mill suit for mineral processing is widely used for selecting ferrous metals, nonferrous metals and nonmetals, as well as precious metals like gold and silver. It mainly consists of driving device, frame, water basin, grinding wheels and grinding base, etc. It grinds ores by wheel driving force: firstly, the power is transferred from the motor to the reducer, then to the horizontal shaft, and finally to the grinding wheel; the wheels then rotate anticlockwise. The wheels can revolve around the vertical shaft of the pan mill, at the same time; it can revolve on its own axis, while the grinding base will remain still. The ores are then pressed, rubbed and grinded repeatedly.

Features of Wet Pan Mill Machine suit for mineral processing

1. Wet pan mill suit for mineral processing after the installation is completed to gold grinding machine groove bottom 5 kilograms of mercury begins normal operation.

2. Each class receive once the Sands, the shift added to 1 kg of mercury to receive the grind at the end of the Sands and mercury, the mercury received gold equipment, with a relatively high density of red cloth mercury screwed out to the package, open the red cloth which left Sands. One kilogram of mercury each class started on it. Containing one is grasping the cloth of gold or grab the gold behind the blanket and put on the mercury board can receive the gold.

Structures of Wet Pan Mill

Advantages of Wet Pan Mill suit for mineral processing

1. The grinding wheels mix up the ores and produce ore pulp while pressing and rubbing the ores.

2. The ores and water are evenly mixed, which makes the pulp density and other indexes stable.

3. After the grinding process, the monomers are taken to the upper surface of the pulp and discharged through the overflow outlet of the water basin. Meanwhile, the coarse ores sink to the bottom of grinding base, being grinded continuously till they reach the required fineness.

4. The screening mesh set up at the overflow outlet of the water basin classifies the ore fineness strictly to avoid the over-grinding and uneven fineness, which helps create better condition for next working process.

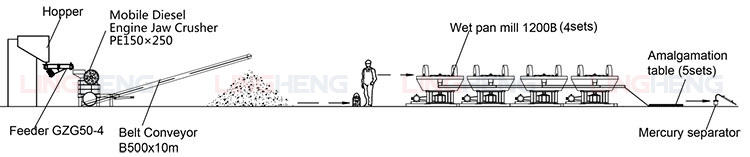

Simple Process Of Gold Dressing

Technical Parameter of Wet Pan Mill

| Model | 1600 | 1400 | 1300 | 1200 | 1100 | 1000 | 900 |

| Dia.of grinding wheel (mm) | 1600(+-)10 | 1400(+-)10 | 1300(+-)10 | 1200(+-)10 | 1100(+-)10 | 1000(+-)10 | 900(+-)10 |

| Thickness of grinding wheel(mm) | 400(+-)20 | 250(+-)20 | 250(+-)20 | 200(+-)20 | 200(+-)20 | 200(+-)20 | 160(+-)20 |

| Dia.of grinding pan (mm) | 2100(+-)30 | 2000(+-)30 | 2000(+-)30 | 1800(+-)20 | 1800(+-)20 | 1800(+-)20 | 1700(+-)20 |

| Thickness of grinding pan (mm) | 200(+-)10 | 170(+-)10 | 150(+-)10 | 90(+-)10 | 90(+-)10 | 90(+-)10 | 80(+-)10 |

| Width of grinding pan (mm) | 360 | 360 | 360 | 230-250 | 230-250 | 230-250 | 170-220 |

| Power (kw) | 25 | 18.5 | 15 | 7.5 | 5.5 | 5.5 |

3 |

| Rotary speed (r/min) | For extract gold: 10-13 other: 18-22 | ||||||

| Input size (mm) | < 25 | ||||||

| Capacity (t/day) | Gold 20 | Gold 20 | Gold 15 | Gold 10 | Gold 8 | Gold 5 | Gold 3 |

| Weight(t) | 14.5 | 8.5 | 7.5 | 5.5 | 5 | 4.5 | 3 |

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!