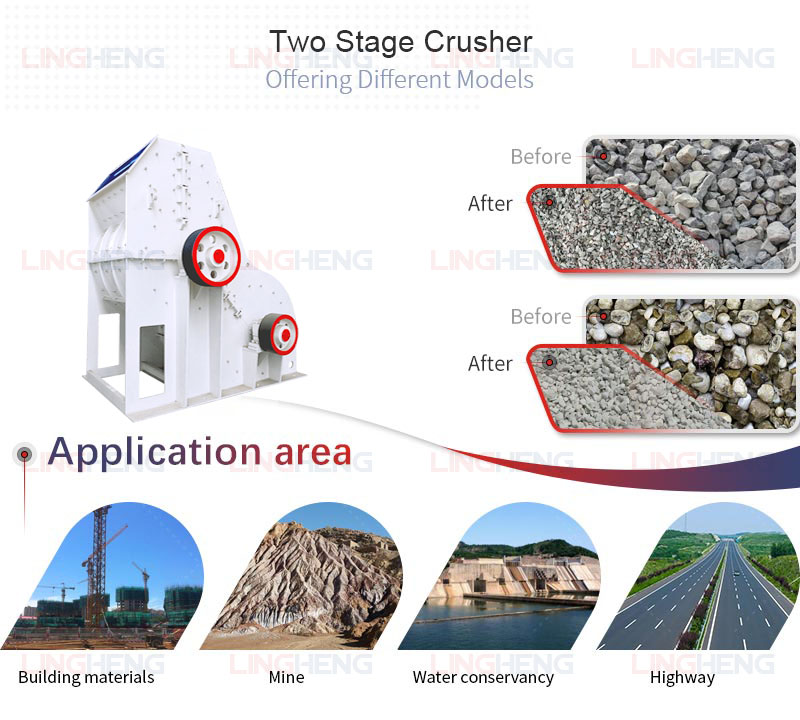

Introduction: Two Stage Crusher is a deformed product of hammer crusher, which can also be called double-stage crusher, two-stage hammer crusher. This two-stage crusher has improved requirement of material humidity. When using this machine crushes materials with high humidity, it can reach better crushing effect. Because it doesn't stick to screen and has no sieve bottom when crushing materials

Two Stage Crusher is a deformed product of hammer crusher, which can also be called double-stage crusher, two-stage hammer crusher. This two-stage crusher has improved requirement of material humidity.

When using this machine crushes materials with high humidity, it can reach better crushing effect. Because it doesn't stick to screen and has no sieve bottom when crushing materials, so, it is also called two-stage crusher without screen.

Applicable Materials of Two Stage Crusher

The Two Stage Crusher can not only adapt to dry materials such as river pebble, basalt, limestone, iron ore, gold and silver mine, construction waste, slag, slag, etc, but also has a good crushing effect on materials with higher water content. Therefore, it has received great attention and recognition in the industry. Two-stage crusher is used in the industries such as construction, chemical engineering, metallurgy, mine, ceramics and refractory matter.

Features of Two Stage Crusher

Less Investment: The double-stage crusher is cheaper, and the overall structure has been improved and optimized. Its volume is effectively reduced by 40%, which can reduce the floor space and the cost of civil works.

Higher Efficiency: The hammerhead is made of high-quality materials, combined with sophisticated technology design so that the crushing efficiency of the equipment can be increased by more than 80%.

Working Principle of Two Stage Crusher

The main difference of two-stage crusher and hammer crusher is that two-stage crusher has two rotors. After having entered the machine, the materials firstly go through first rotor for primary crushing, and the primarily crushed materials are fallen to second rotor for secondary crushing so as to realize required granularity. What's more, the two-stage crusher is without bottom screen so as not to clog sieve pour because of too wet materials. Beside, the two-stage crusher has no requirements for humidity of materials.

Technical Data of Two Stage Crusher

| Model | Capacity(t/h) | Power(kw) |

| SPC600*400 | 10-15 | 18.5kw+18.5kw |

| SPC600*600 | 10-30 | 22kw+22kw |

| SPC800*600 | 18-55 | 45kw+55kw |

| SPC1000*800 | 22-90 | 55kw+75kw |

| SPC1200*1000 | 30-120 | 90kw+110kw |

| SPC1400*1200 | 40-140 | 132kw+160kw |

| SPC1600*1400 | 50-180 | 160kw+200kw |

The tow stage crusher are sold to more than 120 countries and regions around the world. Such as Malaysia, South Africa, Zimbabwe, Philippines, Indonesia and other countries.

Inquiry* Describe Your Buying Requirements in Detail,We will reply you in 24 hours!